|

©2015 CALVINO architecture studio, inc all contents of this publication whether in digital or analog format are the express property of CALVINOarchitecture studio, inc. and shall not be reproduced by any means without written consent from Mike Calvino |

|

Ruskin House Screen Enclosure Upgrade |

|

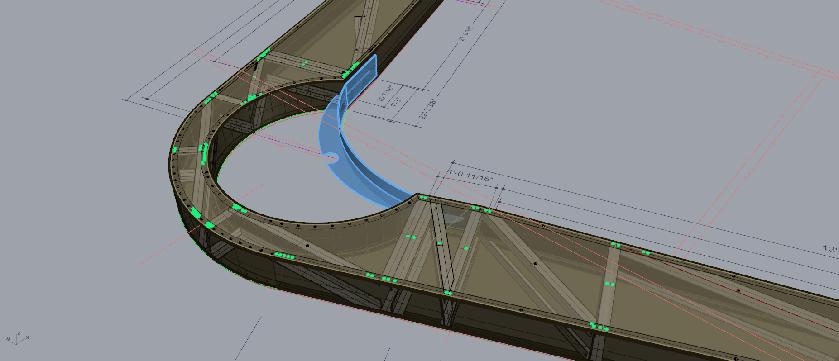

Right: Curved channel section at the "knee" of the beams. |

|

Right: Nest drawing of CNC plasma cut aluminum pieces for connector plates, spacers for the cover sheets, and curved flanges for the curved channel pieces at the "knee" of the beams. |

|

Right: First 8 or so flanges were cut with a router bit, but it proved to be slower than the plasma. |

|

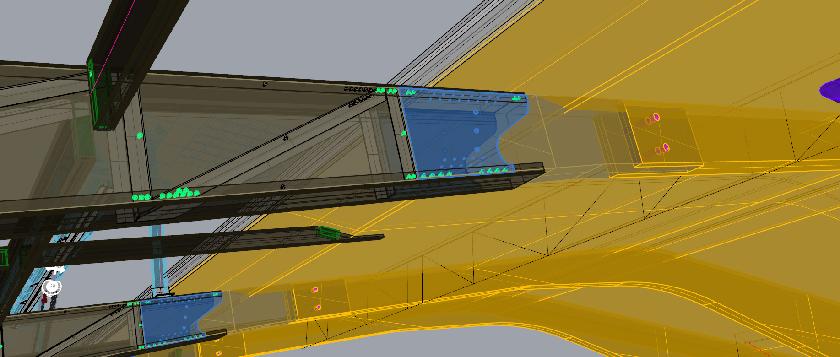

Images are shown ghosted to see composition of parts. This shows the connection to the existing beams. |

|

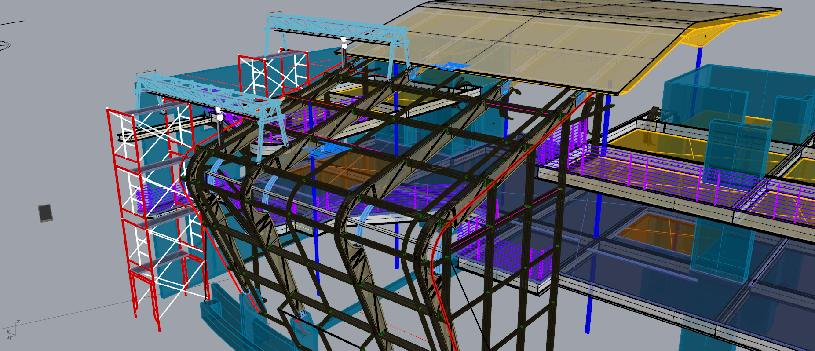

Overall image of scaffolding / hoist trusses to perform the beam swap-out. |

|

Note the split off screen spline edge on the right side of the extrusion. Too bad, the curved sections will have to be fabricated from flat sheet, CNC cut, welded, ground, and have a baked enamel finish applied to match the extrusions. |

|

The metals roller to create the curved sections. We tried rolling the screen extrusion, but the radius was too tight and one of the flanges separated from the web at the screen spline groove. |

|

Screen channel roll attempt. This would have saved considerable time & expense if it would have worked. |

|

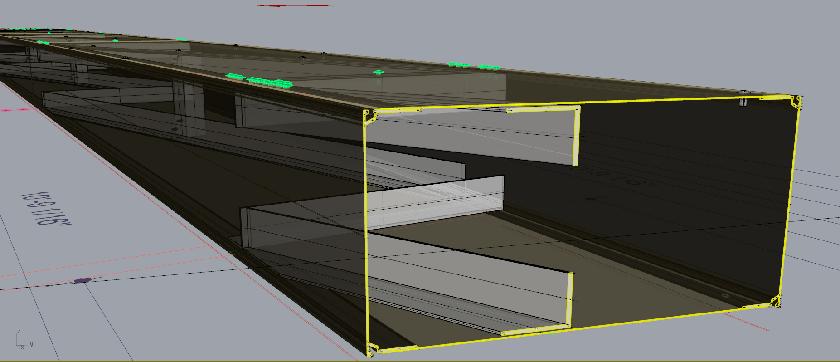

2014-11- Fabrication is in progress cutting all of the members for the truss/beams. The curved knee sections are CNC plasma cut 1/8" aluminum sheet & custom rolled aluminum flat strips, then welded into the C-channel, and sent out for a Kynar, baked enamel finish to match the bronze of the screen extrusions. The 0.040 face sheets are cut out of 4'x10' aluminum sheet with the CNC router with the rivet holes drilled by the machine prior to cutout. Truss diagonals are being cut to length & ends trimmed to correct angles. Assembly of the truss sections will begin once all of the diagonals are cut. |