|

|

||

|

Back to Automation/CNCMachines |

||

|

Design Log ~2010 |

||

|

Right: Early sketch of a 5 axis trussed gantry machine around 2009/early 2010 |

||

|

|

||

|

Right: Early sketch of a/c head |

||

|

Right: elevation from CAD model with misc. 2d extracted cut geometry showing |

||

|

Right: View of Rhino model with misc. 2d extracted cut geometry showing. |

||

|

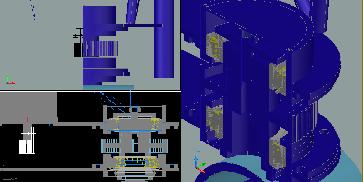

Right: Early model in AutoCad prior to switching to Rhino3d. |

||

|

Right (next 4 images) : Early model in AutoCad prior to switching Rhino3d. The geometry and configuration remained basically the same but was refined as fabrication progressed and issues were worked out. The nice thing about ACAD was its powerful block tech. It could essentially create your material/component lists with as much information as you wanted to input. In the end, Grasshopper for Rhino works far beyond the block tech. |

||

|

Right: View of Rhino Model--wire frame view has its advantages. |

||

|

Right: View of Rhino Model--most modeling I do in ghosted mode. |

||

|

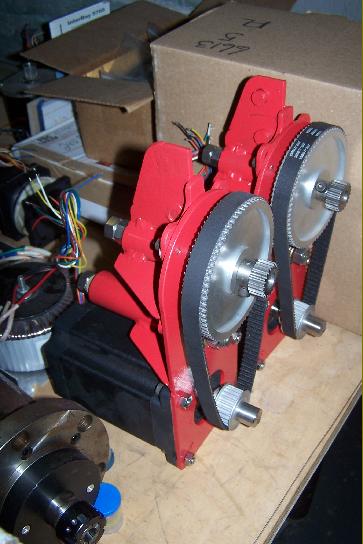

Right: Y carriage block being worked on. |

||

|

|

||