|

|

||

|

Back to Automation/CNCMachines |

||

|

Build Log 07 Spindle and A/C Head Motion 2010 |

||

|

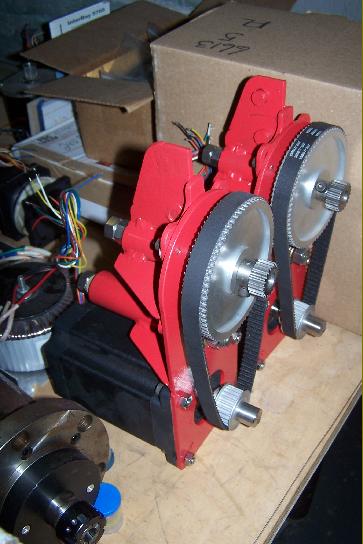

Ok, so this video shows up in build log 5 & 6 too, but it was a bit of a milestone. 5 axis motion even it is manual. |

||

|

So one issue was the electrical connector being too tight in the A fork. The solution was to machine the restraining nut so that the cable could come out the side of it and then clear with enough tolerance. |

||

|

Right & Far Right: you can see the initial clearance issue. |

||

|

Right: The first thought on the electrical plug was to replace the plug, but finding one that would fit the housing proved fruitless. |

||

|

Right & Below: The spindle did not come with a collet wrench and the flats are very narrow. So the solution is to just plasma cut a wrench. |

||

|

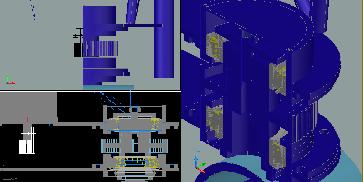

Right: the cooling system had to be mounted as close to the spindle as possible because of the resistance in the coolant hoses. Keeping them small was key to keep the flexibility for motion, but this creates back pressure in the lines and minimizes the length the hoses can be. The mointing position worked out on the back side of the & carriage. All of this adds weight to the top of the gantry and makes oscillations increase with lower frequency but greater amplitude. |

||

|

Right: Sketches for the cooling system and the final configuration in photos. |

||

|

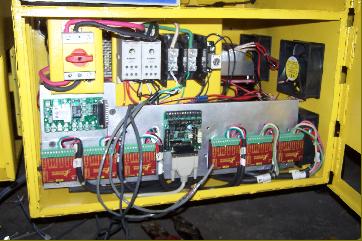

Far Right: The spindle VFD--controller for the spindle motor--wiring for this & mounting can be found in BuildLog09. |

||

|

|

||