|

|

||

|

Back to Automation/CNCMachines |

||

|

Build Log 11 Delivery and setup 2010 |

||

|

Once it was shrink wrapped, it did look a little futuristic maybe . . . I stopped at a Waffle House for breakfast one morning and these guys were looking at me sorta funny like . . . I finally asked them how they were that morning & got to talking a bit, they finally asked what it was as they could see it out the window, & said they thought it maybe was some sort of top secret hovercraft or something . . . That was great! But I did explain what it was and they seemed to be quite intrigued. |

||

|

First we have to get it out of the shop! We had to take out the glass wall & the temporary door. |

||

|

Next task was to design and make some sort of ramps that would allow the machine to roll onto the trailer across the gap, keep the wheels from rolling off the edge of the ramp. The solution is these pivot ramp trusses with a 4" Chanel for the top chord and lateral P1.5" pipes for the pivot points that attach to the trailer at the ramp locations using the same attachment rods. This will also allow me to get the machine off the trailer by attaching it to a 5ton winch, rolling it back to just past the pivot point where it can be tilted with little effort because it will be perfectly balanced like a seesaw, then the winch can be let out and it will roll off the ramps & into the warehouse where it will live for the foreseeable future. |

||

|

Shrink wrapped & rolling . . . Probably I-10. |

||

|

Here we are at the FabLab warehouse in Arkansas . . |

||

|

Here's the roll-off maneuver as I described above the key to this is the floor jack under the free end with a piece of W8 fabricated with end hooks to lock into the trusses at a diagonal connection and lower it with control. You can see the floor jack under the ramps & machine in the far right photo. |

||

|

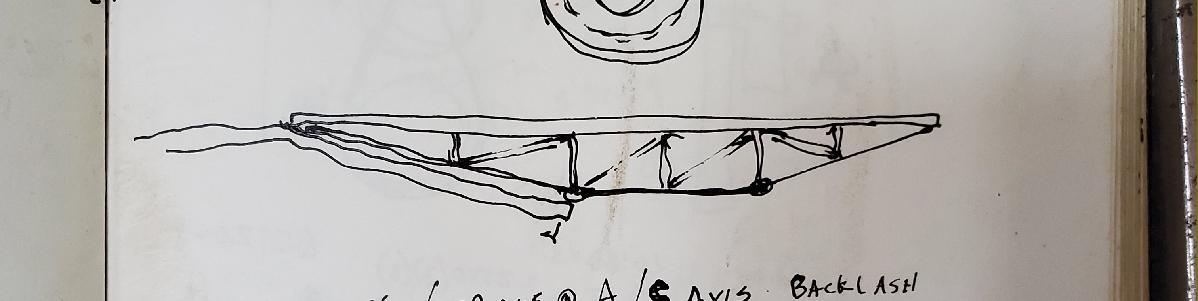

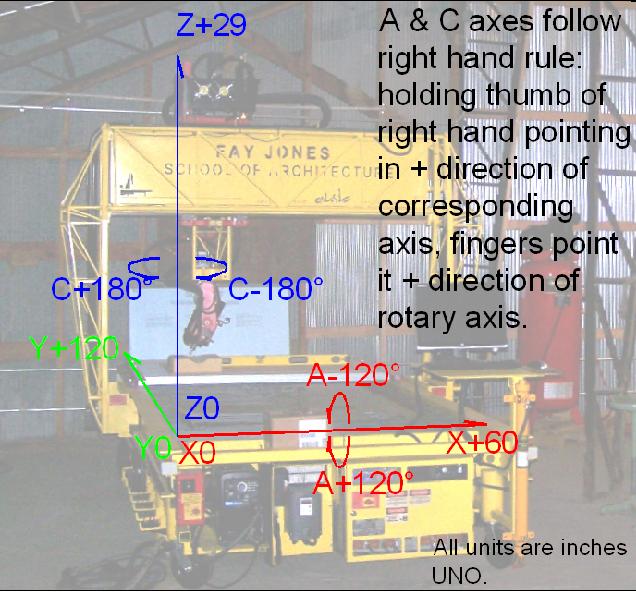

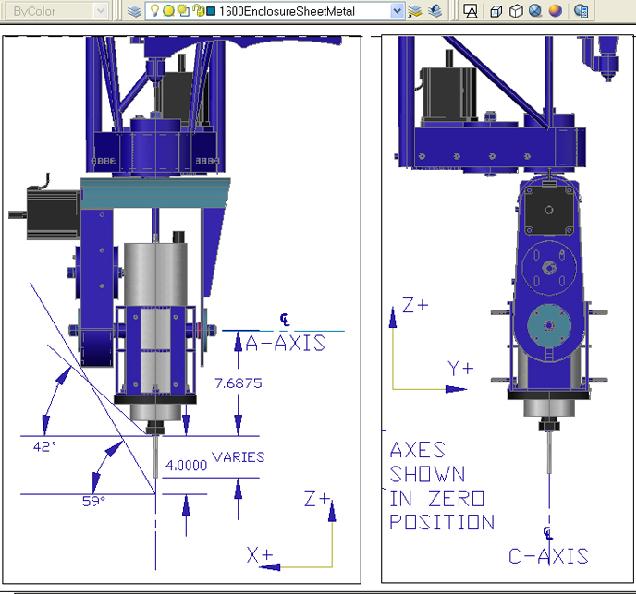

Some orientation sketches to understand the terminology of the machine and Gcode. |

||

|

Ready to roll out . . . |

||

|

|

||